In the fast-paced world of fashion, textiles, and leather goods, standing out from the crowd is no longer a choice—it’s a necessity. Today’s consumers crave uniqueness, durability, and premium quality, while brands struggle to balance creativity with production efficiency. If you’re tired of flat, generic logos, easily worn-off embossments, or limited design flexibility, it’s time to embrace a game-changer: the 3D Silicone Printing Garment Embossing Trademark Textile Leather Embossing Machine. This innovative equipment isn’t just a tool—it’s a catalyst for transforming your products from ordinary to extraordinary.

Why 3D Silicone Embossing? The Market Demand That’s Shaping the Industry

Think about the last time you picked up a high-end jacket, a luxury leather bag, or a premium sportswear piece. What caught your eye first? Often, it’s the subtle yet striking 3D logo, the tactile silicone patch, or the raised embossed pattern that screams “quality.” According to recent industry reports, demand for 3D-textured textile and leather products has surged by 40% in the past two years—driven by brands aiming to enhance brand recognition and consumers seeking tactile, long-lasting designs.

Traditional embossing methods fall short here: heat transfer logos peel off after a few washes, screen-printed designs lack depth, and metal molds limit intricate detailing. This is where 3D silicone printing embossing machines step in. By combining advanced silicone material properties with precision 3D printing technology, they deliver embossments that are not only visually stunning but also durable, flexible, and resistant to water, friction, and fading.

Key Features: What Makes Our 3D Silicone Embossing Machine a Must-Have

Our 3D Silicone Printing Garment Embossing Machine isn’t just another piece of equipment—it’s engineered to solve the biggest pain points of textile and leather manufacturers. Here’s what sets it apart:

1. Unmatched Design Flexibility for Trademarks & Patterns

Whether you’re creating a tiny 3D logo for a kids’ onesie, a bold silicone patch for a denim jacket, or an intricate embossed pattern for a leather wallet, this machine handles it all. With support for 0.1mm-5mm embossing height and compatibility with CAD design files, you can turn any creative concept into reality—no more compromising on detail. From sharp edges to smooth curves, every element of your trademark or pattern is reproduced with pixel-perfect accuracy.

2. Versatility Across Materials: Garments, Textiles, Leather & More

Forget investing in separate machines for different materials. Our embossing machine works seamlessly with:

- Cotton, polyester, spandex, and blended fabrics (ideal for sportswear, activewear, and casual apparel)

- Genuine leather, PU leather, and vegan leather (perfect for bags, shoes, belts, and accessories)

- Fleece, neoprene, and even technical fabrics (great for outdoor gear and loungewear)

This versatility lets you expand your product line without adding extra equipment costs.

3. Durable, Washable, & Eco-Friendly Silicone Results

Silicone is the star material here—and for good reason. Embossments created with our machine are:

- Wash-resistant: Withstand up to 50+ washes at 60°C without peeling, cracking, or fading (a huge upgrade from traditional heat transfers).

- Eco-friendly: We use non-toxic, FDA-approved silicone that meets OEKO-TEX® and REACH standards—appealing to eco-conscious brands and consumers.

- Flexible: The silicone retains its shape even after repeated stretching (perfect for stretchy sportswear or form-fitting garments).

4. High-Speed Production for Scalability

Creativity shouldn’t slow down your workflow. Our machine boasts a production speed of up to 500 pieces per hour (depending on design size), making it ideal for both small-batch custom orders and large-scale mass production. The automatic feeding and temperature control system also reduces human error, ensuring consistent quality across every piece.

Real-World Applications: How Brands Are Using It to Stand Out

Don’t just take our word for it—see how leading brands are leveraging this technology to elevate their products:

- Athletic Wear Brand : Used the machine to create 3D silicone logos on their running leggings. The logos are not only eye-catching but also provide a non-slip grip, solving a common customer complaint about logos sliding during workouts. Sales of the leggings increased by 25% within three months.

- Leather Accessory Brand : Replaced traditional metal-stamped logos with 3D silicone embossments on their leather bags. The softer, more tactile logo received rave reviews from customers, and the brand reported a 30% increase in repeat purchases.

- Children’s Apparel Brand : Created fun 3D silicone patches (shapes like dinosaurs and unicorns) for their kids’ jackets. Parents loved that the patches were durable and non-toxic, while kids adored the playful, raised designs—driving a 40% boost in holiday sales.

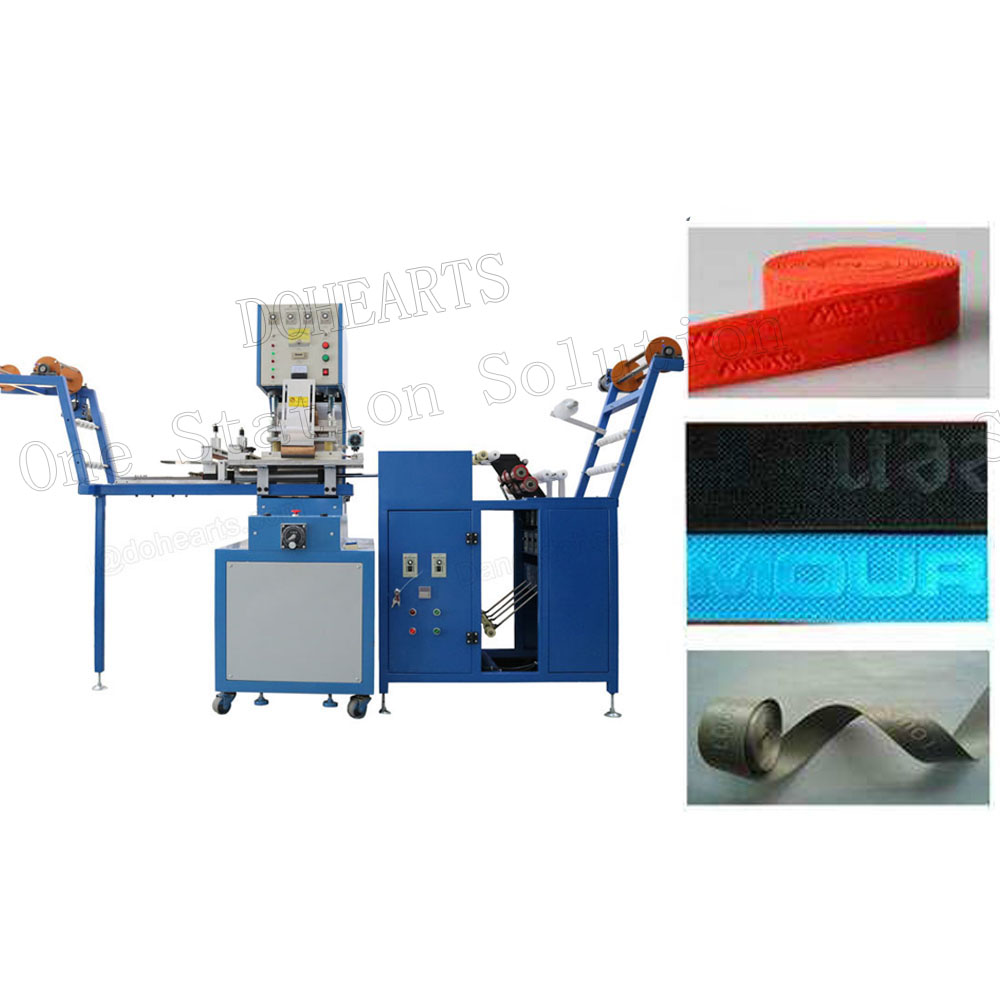

Samples

Why Invest Now? The Competitive Edge You Can’t Afford to Miss

In a market where consumers judge products by touch as much as sight, 3D silicone embossing isn’t just a trend—it’s the future of textile and leather branding. By investing in our 3D Silicone Printing Garment Embossing Machine, you’re not just buying equipment—you’re:

- Enhancing your brand’s perceived value (3D embossments make products look more premium).

- Reducing production waste (no more scrapping items with faulty logos).

- Opening doors to new clients (brands are actively seeking manufacturers who offer 3D silicone options).

Ready to Transform Your Products?

Whether you’re a small workshop looking to expand your capabilities or a large manufacturer aiming to stay ahead of the competition, our 3D Silicone Printing Garment Embossing Trademark Textile Leather Embossing Machine is the solution you need. We offer personalized demos, training, and after-sales support to ensure you get the most out of your investment.

Don’t let flat, forgettable designs hold your brand back. Elevate your texture, boost your brand recognition, and delight your customers—one 3D embossment at a time.

Contact us today to schedule a demo and learn how we can tailor this machine to your unique production needs. Your next best-selling product starts here.

Post time: Sep-18-2025