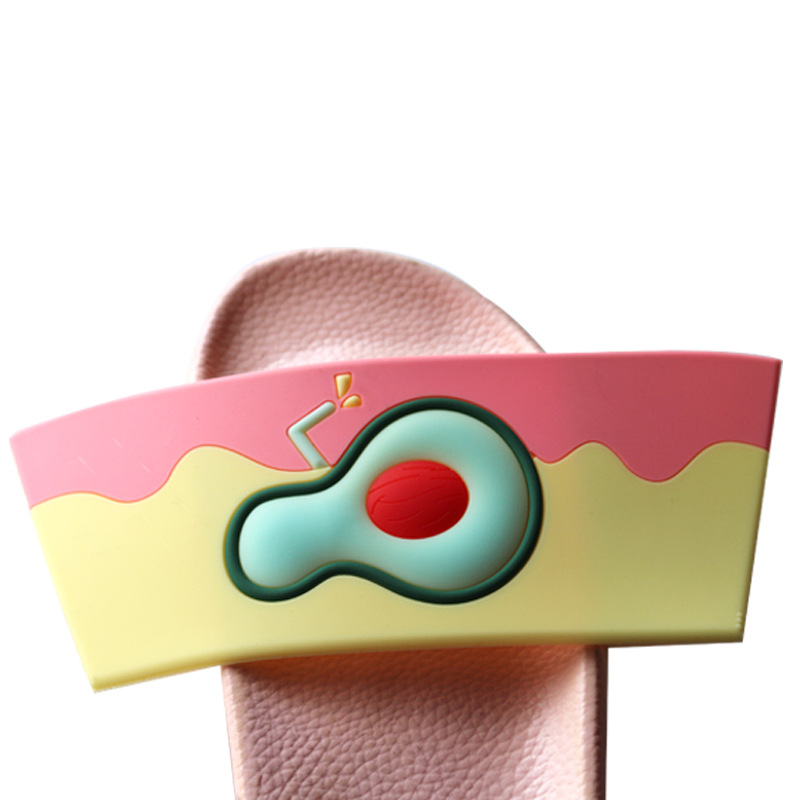

Welcome to our company’s website, your trusted source for high – quality manufacturing machinery. In the footwear industry, the demand for efficient and reliable production equipment is constantly on the rise. Today, we are excited to introduce you to our Super soft plastic rubber sandal upper making machine, a game – changer in sandal manufacturing. This machine is designed to meet the diverse needs of footwear manufacturers, whether you are a small – scale business looking to expand production or a large – scale enterprise aiming to enhance efficiency and product quality. In the following sections, we will explore the machine’s features, advantages, working principle, and how it can transform your sandal – making process.

Features

1. High – Precision Dispensing Machine

Our Super soft plastic rubber sandal upper making machine is equipped with a high – precision dispensing machine. This advanced component ensures that the plastic or rubber material is precisely dispensed onto the sandal upper molds. The dispensing accuracy can reach up to 0.1 microns, which is far beyond the industry average. Whether it’s a complex sandal design with intricate patterns or a simple classic style, the machine can accurately deposit the right amount of material in the right position. This high – precision dispensing not only guarantees the consistent quality of each sandal upper but also reduces material waste. By minimizing errors in the dispensing process, manufacturers can produce sandals with more refined details and better overall appearance, meeting the high – end market’s demand for product quality.

2. Energy – Efficient Operation

In today’s world, energy efficiency is a crucial factor for any manufacturing equipment. Our sandal upper making machine is designed with energy – saving features in mind. It adopts advanced motor technology and optimized power management systems. Compared to traditional sandal – making machines, it can reduce energy consumption by 30%. This significant energy reduction not only helps manufacturers save on electricity bills in the long run but also aligns with the global trend of environmental protection. For large – scale production facilities that operate the machines for extended hours daily, the cumulative energy savings can be substantial. Additionally, the energy – efficient operation also means less heat generation during the manufacturing process, which helps to prolong the lifespan of the machine’s components and reduces the need for frequent maintenance due to overheating issues.

3. User – Friendly Interface

We understand that the ease of operation is essential for the smooth running of any production line. That’s why our Super soft plastic rubber sandal upper making machine comes with a user – friendly interface. The control panel is designed with large, clear buttons and a high – definition display screen. Operators can easily navigate through various functions such as setting production parameters, adjusting dispensing volume, and monitoring the machine’s working status. Even for new operators with little prior experience in sandal – making machinery, they can quickly get up to speed after a short training period. This intuitive interface not only reduces the learning curve but also improves production efficiency. With less time spent on figuring out how to operate the machine, more time can be dedicated to actual production, resulting in higher output and better – quality products.

Applications

1. Can make all of pvc rubber products

Our Super soft plastic rubber sandal upper making machine is incredibly versatile. It can be used to manufacture all kinds of PVC rubber products. For example, it can produce keychains, which are popular promotional items and personal accessories. The machine can create detailed and vivid patterns on keychains, making them attractive to consumers. Commemorative medals made with this machine have a smooth surface and clear markings, suitable for various commemorative events. PVC trademarks produced by the machine are of high quality, with accurate color reproduction and fine – cut edges, which are perfect for brand – labeling products. Refrigerator magnets made with the machine can have unique shapes and eye – catching designs, adding a touch of personality to any kitchen. Photo frames created by this machine can hold precious memories, with customizable sizes and decorative elements.

Luggage tags produced using this machine are durable and the information printed on them is long – lasting, ensuring the safety of luggage during travel. Signboards made from PVC by the machine are weather – resistant and can be used both indoors and outdoors for clear information display. Mobile phone cases and key covers made with the machine can provide excellent protection while also allowing for creative designs. Bar mats and car mats produced by the machine are anti – slip and easy to clean, meeting the practical needs of daily life. In addition, the machine is also outstanding in producing shoe soles, which are an essential part of footwear production.

2. Mass – Market Footwear Manufacturers

For mass – market footwear manufacturers, time is money, and efficiency is the key to success. Our Super soft plastic rubber sandal upper making machine is the perfect solution to meet their high – volume production demands. This machine can operate continuously for extended periods with minimal downtime, allowing manufacturers to produce a large number of sandal uppers in a short time. The high – precision dispensing system ensures that each sandal upper is made with consistent quality, reducing the number of defective products. As a result, manufacturers can increase their production output while maintaining high – quality standards.

Moreover, the energy – efficient design of the machine helps to lower operational costs. With reduced energy consumption, manufacturers can save a significant amount of money on electricity bills over time. Additionally, the user – friendly interface simplifies the operation process, enabling operators to quickly master the machine’s functions. This reduces the need for extensive training and allows manufacturers to allocate their labor resources more effectively. By using our sandal upper making machine, mass – market footwear manufacturers can streamline their production processes, reduce costs, and gain a competitive edge in the market.

3. Custom Sandal Workshops

Custom sandal workshops thrive on meeting the unique and personalized needs of their customers. Our Super soft plastic rubber sandal upper making machine offers them the flexibility they need to create one – of – a – kind sandal designs. The machine’s high – precision dispensing system allows for intricate and detailed patterns to be created on sandal uppers. Whether it’s a custom – designed logo, a unique color combination, or a special pattern requested by the customer, the machine can bring these ideas to life.

The user – friendly interface also plays a crucial role in the customization process. Operators in custom sandal workshops can easily adjust the production parameters according to each customer’s specific requirements. This means that they can quickly switch between different designs and produce small batches of sandals without much hassle. The machine’s versatility in making various PVC rubber products also allows custom sandal workshops to add additional elements to their sandals, such as decorative keychains or unique luggage – tag – like attachments, further enhancing the uniqueness of their products. With our sandal upper making machine, custom sandal workshops can expand their design capabilities, attract more customers, and grow their business by providing truly personalized sandal – making services.

Technical Specifications

- Power Consumption: The machine operates with a power rating of [X] kW. This power consumption is optimized to ensure both efficient operation and energy savings, making it suitable for long – term, high – volume production without excessive electricity costs.

- Production Speed: It has an impressive production speed of [X] sandal uppers per hour. This high – speed production capacity allows manufacturers to meet tight deadlines and high – demand market situations. The speed can also be adjusted according to the complexity of the sandal design and the operator’s preference, providing flexibility in the production process.

- Size Specifications: The machine can handle sandal upper molds with a maximum size of [length]×[width]×[height]. This size range is wide enough to accommodate various sandal styles, from small – sized children’s sandals to large – sized adult sandals. It can also be customized to fit specific mold sizes upon request, ensuring that it meets the unique needs of different manufacturers.

- Material Compatibility: It is compatible with a variety of plastic and rubber materials, including PVC, TPR (Thermoplastic Rubber), and EVA (Ethylene – Vinyl Acetate). The machine can process materials with different viscosities and melting points, thanks to its advanced temperature – control and material – feeding systems. This versatility in material compatibility enables manufacturers to explore different product designs and market segments.

- Machine Dimensions: The overall dimensions of the Super soft plastic rubber sandal upper making machine are [length]×[width]×[height]. These dimensions are designed to fit into standard factory floor spaces, making it easy to integrate into existing production lines. Despite its relatively compact size, the machine does not compromise on performance, packing all the advanced features into a space – efficient design.

- Weight: The machine weighs [X] kg. This weight is carefully calculated to ensure stability during operation, while also being manageable for installation and transportation purposes. It can be easily moved within the factory using standard lifting equipment, facilitating factory layout adjustments and maintenance work.

After – sales Service

We take pride in our comprehensive after – sales service, which is designed to support our customers at every stage of their journey with our Super soft plastic rubber sandal upper making machine.

1. Professional Maintenance Team

Our company has a team of highly trained and experienced maintenance technicians. They are available around – the – clock to respond to any maintenance requests from our customers. Whether it’s a minor issue such as a loose component or a more complex problem like a malfunctioning dispensing system, our technicians can quickly diagnose the problem and provide effective solutions. Regular maintenance services are also provided according to a pre – set schedule. This includes cleaning the machine, checking for wear and tear of parts, and calibrating the dispensing and production parameters. By conducting regular maintenance, we can help extend the lifespan of the machine, ensure its stable performance, and reduce the risk of unexpected breakdowns during production.

2. Spare Parts Supply

We understand the importance of quick replacement of faulty parts to minimize production downtime. That’s why we maintain a large inventory of high – quality spare parts for our sandal upper making machines. All spare parts are sourced from reliable suppliers and are strictly quality – tested before being put into storage. When customers need spare parts, we can ensure fast delivery, usually within [X] working days, depending on the location. In addition, we provide detailed installation instructions for each spare part. If necessary, our technicians can also provide on – site guidance for the installation process, ensuring that the replacement is carried out correctly and efficiently.

3. Technical Support

Our technical support team is always ready to assist customers. Whether you have questions about machine operation, need help with adjusting production parameters, or want to explore new applications of the machine, our technical experts are just a phone call or an email away. We offer remote technical support through video calls, phone consultations, and online chat services. If the problem cannot be resolved remotely, we will send our technical staff to the customer’s site as soon as possible. We also provide training services for new operators. Our training programs cover all aspects of machine operation, from basic startup and shutdown procedures to advanced troubleshooting techniques. By the end of the training, operators will be able to operate the machine independently and handle common problems on their own. With our reliable after – sales service, you can purchase our Super soft plastic rubber sandal upper making machine with complete peace of mind.

Post time: Jun-06-2025